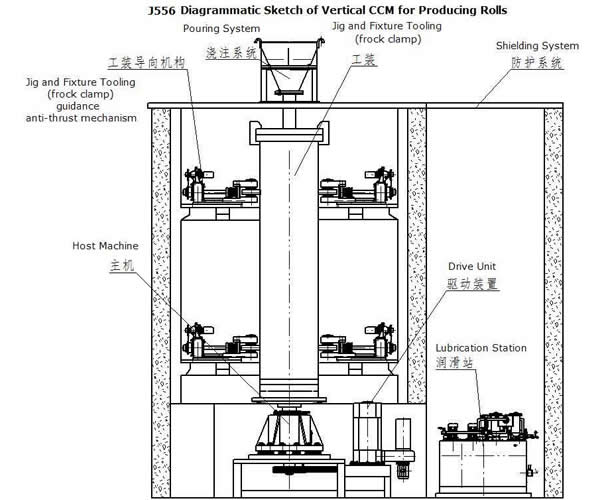

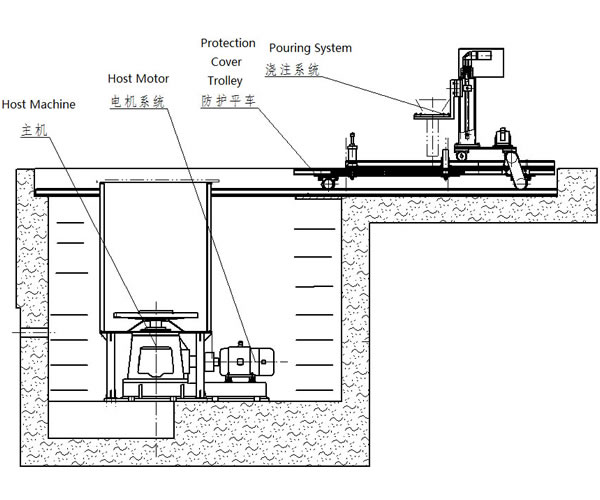

Vertical Duplexed Mill Roll Centrifugal Casting Machine

Our vertical centrifugal casting machines are used to produce the duplexed

mill rolls. The roll casting process divided into two steps. The first step is

the vertical centrifugal casting of roll shell/outer layer, the second step is

the vertical static casting of roll core. The two steps are proceeded

continuously in sequence. After the static casting is finished, the newly casted

roll will be positioned in the ground pit for curing for 24 hours in a certain

degreed temperature. With the high degree of mechanization, both process of the

vertical centrifugal casting and static casting can be processed and finished in

one machine, thus the casting job can be done with high efficient and labor

saving.

The vertical mill roll centrifugal casting machine adopts fully automated

systems utilizing programmable logic controllers (PLC) with functions of

automatic pouring, automatic mold coating, automatic mold inner wall cleaning

and automatic extraction. The duplexed mill roll’s diameter ranged from 200mm to

1,500mm with length ranged from 500mm to 5,000mm.

Key Features of Vertical Type Centrifugal Casting machine

PLC Automatic operation.

Stepless Speed Governing plus frequency conversion motor force driving.

Produce castings with superior metallurgical structure.

Mechanical mold inner wall coating and cleaning.

Centrifugal Casting Machine Models & Casting Specifications

| Model | Min. & Max. Dia. (mm) | Length (mm) | Total Load: Mold + Casting |

|---|---|---|---|

| J554 | 200-400 | 2,000 | 4,000kg |

| J556 | 500-600 | 2,000 | 8,000kg |

| J558 | 700-800 | 3,000 | 10,000kg |

| J55100 | 900-1,000 | 4,000 | 25,000kg |

| J5515 | 1000-1,500 | 5,000 | 30,000kg |