automatic Centrifugal Casting Machine for Jewelry

1/. Semi-automatic centrifugal casting machine from China.

Application:

It is used to produce casted buckles and accessories for the leather industry and garment industry,

Imitation jewellery, promotion gifts, medal, and figurines etc from zinc alloy or tin alloy.

Features:

1. Digital speed display.

2. Digital timer for centrifugal time setting.

3. Cover Automatic open / close design, effectively saving time and labor.

4. Adopt variable frequency driver for speed regulation in range 50-1400 RPM for more processing Options

5. Safety protection of the centrifugation area

6. Electronic emergency brake system

7. Fan for mould cooling.

8. Easy operated and maintained.

Semi-Automatic vacuum Centrifugal Casting Machine

Application:

It is used to produce precision casted buckles and accessories for the leather industry and garment

industry, imitation jewelry, promotion gifts, medal, and figurines etc from zinc alloy or tin-lead alloy.

Features:

1. Efficient vacuum pump, centrifugal casting cycle shorted, cooling faster, rubber mold working life

prolonged

2. Digital speed display.

3. Digital timer for centrifugal time setting.

4. Cover Automatic open / close design, effectively saving time and labor.

5. Adopt variable frequency driver for speed regulation in range 50-1400 RPM for more processing

options

6. Safety protection of the centrifugation area

7. Electronic and pneumatic double emergency brake system

8. Easy operated and maintained.

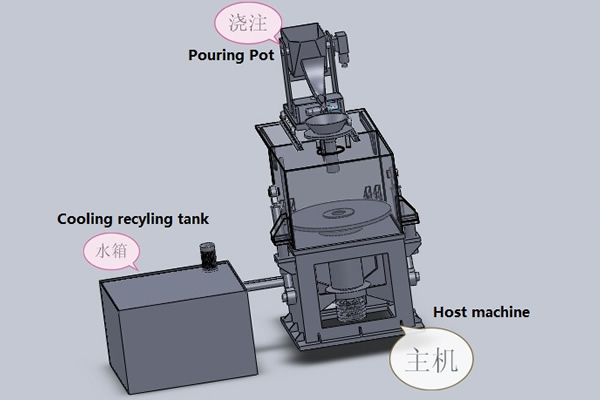

Semi-Automatic 3-Stataion Centrifugal Casting Machine

Application:

It is used to produce casted buckles and accessories for the leather industry and garment industry, imitation jewellery, promotion gifts, medal, and figurines etc from zinc alloy, tin alloy, other metals, wax, or resin. Production output up to 200 casting operations per hour.

Features

Welded Steel structure

Precious Index rotary table

Independent mould camping pressure system with independent pressure regulator and pressure gauge

Variable frequency drive adjust centrifugal speed from 0-1400 rpm

Safety protection of the centrifugal area.

Fan Forced mould cooling.

Touch Screen setting panel display all functions, time, speed.

PLC setting and controlling all cycle functions.

Automatically diagnoses whether the rubber mold is placed or not.

Easy operated and maintained