Cantilever Centrifugal Casting Machine

Horizontal Cantilever/shaft Centrifugal Casting Machine

Our horizontal Cantilever/shaft Centrifugal Casting Machines are used to produce the big diameter bronze or copper alloy tubes, cylinder liners, alloy tubes, brake drums etc. The cantilever centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers (PLC) with functions of automatic pouring, automatic mold coating, automatic mold inner wall cleaning and automatic casting ejection by hydraulic shaft. The casted product’s diameter ranged from 100mm to 1,000mm with length ranged from 50mm to 1,000mm.Key Features of Vertical Type Centrifugal Casting machine

PLC Automatic operation.Stepless Speed Governing plus frequency conversion motor force driving.

Produce castings with superior metallurgical structure.

Mechanical mold inner wall coating and cleaning.

Automatic casting ejection by hydraulic shaft.

Safety guard of shield cover to prevent the hot metal and cooling water from splashing.

Centrifugal Casting Machine Models & Casting Specifications

| Model | Min. & Max. Dia. (mm) | Length (mm) | Total Load: Mold + Casting |

|---|---|---|---|

| J515 | 50-500 | 600 | 600kg |

| J516 | 70-600 | 700 | 2,00kg |

| J517 | 100-700 | 900 | 4,000kg |

| J519 | 100-900 | 1050 | 8000kg |

| J5110 | 200-1,000 | 1,000 | 10,000kg |

Cantilever Centrifugal Casting Machine

Cantilever Centrifugal Casting Machine

Babbitt Lining Centrifugal Casting Machine

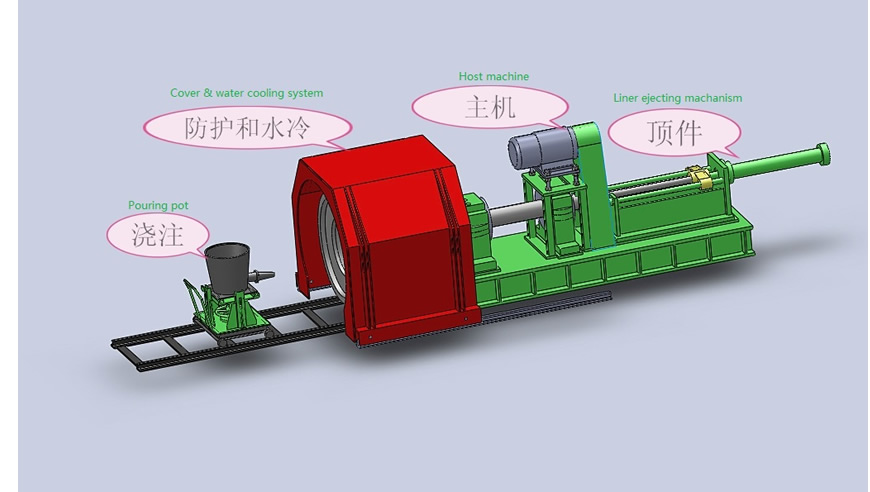

Cantilever/Spin-Head Centrifugal Casting Machine 3D Drawing

Cantilever/Spin-Head Centrifugal Casting Machine Mold Heating System